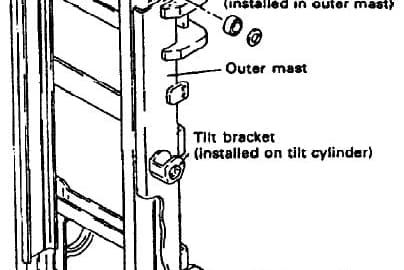

Below, you’ll find an illustration of reach trucks that shows some of the important parts and components.

They can increase productivity and efficiency dramatically. Reach trucks specialize in narrow-aisle warehouses and distribution centers. Secondly, it allows the warehouse operator to maximize space by accessing otherwise inaccessible pallet positions that are high and deep, which a regular forklift is unable to access. Firstly, they have a tight turning radius which is required for operating in narrow aisles warehouses.

There are two major advantages to using reach trucks, compared to other types of forklifts. Alternately, they are also used to retrieve cargo from the staging area for putaway into storage racks. In these types of operations, reach trucks are expected to retrieve cargo from any type of pallet position and place them in the staging area. Reach trucks are often found in warehouses, distribution centers, container freight stations (CFS), and manufacturing facilities that have narrow aisles or high rack storage areas. Reach trucks are equipped with a telescopic mast that allows them to access pallets up to 46 feet high and a pantograph mechanism that can retrieve pallets two or three deep. One common type of MHE is a reach truck.Ī reach truck is a type of forklift that is designed to operate in warehouses that have narrow aisles, due to their ability to easily rotate and their compact design. These are commonly racking systems, pallets, warehouse management systems, and also material handling equipment (MHE). Warehouses optimize productivity and space by using various types of equipment.

0 kommentar(er)

0 kommentar(er)